In today's world of increasingly effective and compact electronics, efficient thermal management is now not a luxury – it's a requirement. Overheating can result in diminished effectiveness, method instability, and in some cases catastrophic failure. that is where tailor made heat sinks can be found in. contrary to off-the-shelf answers, tailor made types are tailor-made to the precise needs of one's software, making certain optimum warmth dissipation and reputable Procedure. This manual will explore the crucial part of custom made heat sinks, especially Extruded Profiles Heatsink, in many industries and supply insights into planning and balancing Value with functionality.

Table of contents:

important Industries That get pleasure from custom made Heat Sink alternatives

the way to layout a custom made Heat Sink for ideal Thermal administration

Price vs. efficiency: Balancing Custom warmth Sink specs

Key Industries That Benefit from tailor made warmth Sink alternatives

a lot of industries count on personalized heat sinks to maintain the overall performance and longevity in their electronic elements. The telecommunications sector, with its dense networking devices, Added benefits considerably from tailor-made thermal alternatives that protect against overheating and assure uninterrupted support. Similarly, the facility electronics field, addressing large-voltage and substantial-existing programs, calls for sturdy warmth sinks to handle the rigorous warmth generated by energy transistors and rectifiers. On top of that, the aerospace and protection industries, the place trustworthiness under Serious problems is paramount, rely upon customized styles to withstand harsh environments and preserve essential method functionality. Even in clinical tools, in which precision and security are crucial, customized warmth sinks Perform an important job in avoiding overheating and making certain precise diagnoses and solutions.

ways to structure a customized warmth Sink for optimum Thermal administration

Designing a good custom made heat sink requires thorough thing to consider of several things. website initial, being familiar with the heat supply and its thermal traits is very important. This features determining the power dissipation, temperature boundaries, and mounting prerequisites. subsequent, choosing the correct product is vital. Aluminum is a well-liked choice resulting from its fantastic thermal conductivity, light-weight, and price-effectiveness, producing Extruded Profiles Heatsink a standard Remedy. Copper delivers superior thermal general performance but is heavier and dearer. The geometry of the heat sink is additionally vital. Fin density, fin height, and base thickness all influence the heat sink's power to dissipate warmth. Computational Fluid Dynamics (CFD) simulations can be used to optimize the design and forecast thermal overall performance right before Bodily prototypes are constructed. Considering airflow and ventilation throughout the enclosure is likewise important, as good airflow boosts the heat sink's efficiency.

Value vs. effectiveness: Balancing personalized Heat Sink requirements

when maximizing thermal functionality is actually a Major target, Value is likewise a major thought when designing custom made heat sinks. better-performance elements like copper will increase the In general Price tag in comparison to aluminum. Similarly, complicated geometries that have to have intricate machining or specialized manufacturing procedures will even push up expenditures. selecting the suitable production method, like extrusion for Extruded Profiles Heatsink, can substantially influence Charge-usefulness. it is vital to diligently Appraise the thermal demands of the application and identify spots where by overall performance may be balanced with Price tag discounts. such as, optimizing fin density or deciding on a far more Expense-efficient alloy can normally give a excellent equilibrium in between thermal general performance and spending budget. Sourcing your custom made heat sinks from respected companies who present structure support and benefit engineering can further more assist in obtaining the optimum Price-functionality ratio. Renxin Precision, as an example, features a range of personalized warmth sink methods and can provide professional steerage on optimizing your layout for equally general performance and value.

In conclusion, personalized warmth sinks are essential elements for ensuring the reliability and functionality of electronic devices in a variety of industries. By comprehension The crucial element structure issues and thoroughly balancing Charge with general performance, you may make a personalized thermal Alternative that meets the specific wants within your software. Do not wait to take a look at the benefits of Extruded Profiles Heatsink and talk to with seasoned producers like Renxin Precision to locate an ideal Answer for your thermal administration worries. start off optimizing your thermal functionality today!

Joshua Jackson Then & Now!

Joshua Jackson Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Michelle Trachtenberg Then & Now!

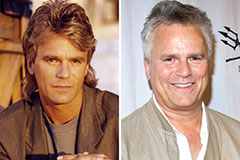

Michelle Trachtenberg Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!